Product center

China Mobile I-EAM6

Six functions

1.Inventory

Product idea:

Inventory app uses Android platform mobile phone or tablet computer as the mobile smart terminal for field work. It can integrate with multiple asset management systems on the server side, and introduce technologies such as bar code and NFC (including high-frequency RFID) to integrate on-site inventory, inventory, and label binding. Business management functions are extended to mobile smart terminals; personnel obtain task and work support information in real time on the site and complete field data collection; and timely feed data from mobile smart terminals to the inventory server server system via Wifi and 3G, Automatically integrate with the management system deployed in the cloud or own server to compare inventory differences and automatically form inventory profit and loss records to achieve intelligent enterprise asset inventory management.

Product brief description: CMEC Equipment Assets Standardization Management Software, designed and developed by CMEC Intelligent Control Technology Co., Ltd. in Guangdong, combined with Android mobile phone, adopts advanced computer technology and communication technology, and is suitable for the company's fixed asset inventory staff. , Establish a mobile intelligent asset inventory platform to efficiently respond to various complex issues in asset inventory work. For different sites or departments, obtain inventory work tasks at any time as needed, making rapid inventory of equipment assets possible.

Brief function description:

Inventory Easy consists of a server-side program and a mobile app, which are used in conjunction with each other to achieve mobile, information, and intelligent inventory.

(A) server-side system

The device inventory function of the EAM server can be easily used with the inventory of the Android mobile phone. It mainly includes: label binding and inventory checking, used to formulate label binding and inventory checking tasks, and downloading to inventory personnel for mobile phone execution.

(II) Inventory the Easy Mobile App

Inventory Mobile App includes: download tasks, upload results, tag binding, inventory tasks, inventory profit processing, inventory loss processing, inventory inquiry, settings and other functions.

Inventory personnel can download the tag binding or inventory task to the mobile inventory app via the wireless network, go to the inventory department responsible for the inventory, and upload the results to the server system after the work is completed. The system confirms the inventory profit and loss.

Value:

Cost saving: ordinary Android phones can be loaded with inventory counting tools, reducing the cost of purchasing industrial PDAs;

Simple and easy to use: APP application based on Android platform, easy to get started and master inventory tools;

Quick inventory: greatly improve inventory work efficiency, reduce inventory workload, and make work easier and faster;

Accurate inventory: Improve the accuracy of inventory, enhance the accuracy of data collection of assets inventory of enterprises and institutions, and quickly find out the entrepreneurs.

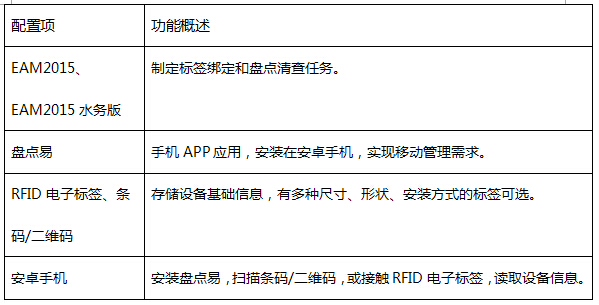

basic configuration

2.Easy inspection

Product idea:

Equipment point inspection is the top priority of enterprise equipment management, especially for process industries that require high continuity. By adopting inspection and inspection, the task can be directly sent to the mobile operator's mobile phone, which facilitates various tasks and timely understands the operating status of various parts of the equipment. Combined with the working standards established by the computer system for regular inspection and maintenance, the work items such as equipment inspection items, standard values, inspection intervals, and hidden trouble elimination in the area inspection are solidified, providing tools and equipment for the compliance management of equipment assets Data support can help to avoid production and equipment from errors, defects, hidden dangers and deterioration to failures that cause downtime and production stoppages, resulting in irreparable huge losses.

Product description:

Guangdong Zhongshe Intelligent Control Technology Co., Ltd. designed and developed the Zhongshe equipment asset standardization management software--Inspection Inspection, combined with Android mobile phones, using advanced computer technology and communication technology, will carry out inspection standards and inspection information. Periodic downloads are stored in mobile phones. As long as the point inspection personnel follow the point inspection task guide in the system, the point inspection can be conveniently performed, and an advanced enterprise point inspection work mode is established.

Features:

Inspection and inspection are composed of a server program and a mobile APP, which are used in conjunction with each other to achieve the mobile, information and intelligent point inspection.

(A). Server-side system

The inspection management of the EAM server is easy to use in conjunction with the inspection of the Android mobile phone. It mainly includes: standard basic management, periodic inspection, spot inspection, location anomaly management and other modules, which are used to define the standard area and what equipment is in a certain area, the standard equipment category and what equipment is in a category, and the inspection equipment category standard. 3. Calibration of inspection area.

(II). Mobile Inspection App

The mobile app for inspection and inspection includes functions such as inspection tasks, tag binding, task random inspection, location management, settings, and data synchronization.

The point inspection personnel can download the point inspection tasks to the mobile inspection easy app through the wireless network, and go to the inspection point [pre-deployed] to perform the inspection work in accordance with the defined inspection area and project in the required time. After the work is completed, the results are uploaded to the server system for comparative analysis of the system to provide a basis for preventive maintenance.

Value:

Cure spot inspection work mode, standardize spot inspection process and improve inspection quality. To ensure the authenticity, timeliness of equipment inspections and the validity of inspection results data, to avoid missing inspections or even inspections during inspections. Managers can check the inspections of equipments at the server. Progress and quality.

Discover equipment anomalies in time to ensure the safe operation of the equipment. Through standard spot inspections, timely discover abnormalities and hidden dangers of equipment, grasp the initial information of equipment failures, and take timely measures to eliminate the failures at the budding stage.

Effectively perform data analysis to obtain equipment failure rules. The inspection results are uploaded directly to the server database, which can analyze and analyze the long-term inspection results of the equipment, and obtain key data on equipment failure rules and daily maintenance.

Carry out preventive maintenance work to prolong the service life of equipment and reduce the production cost of enterprises. Combining various types of data from inspection results and the information provided by the fault analysis system, managers use this as an important basis for formulating pre-maintenance strategies, propose reasonable parts repair and replacement plans, continuously summarize experiences, improve technical standards, and maintain equipment Highly stable performance.

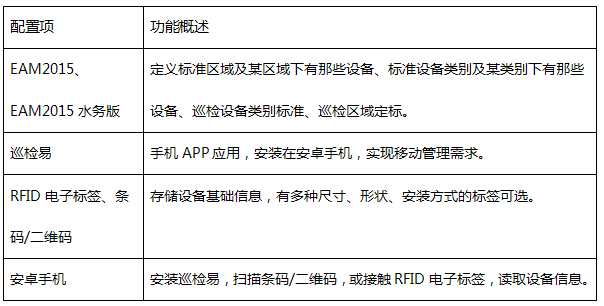

basic configuration

3.Mobile work order

Product idea:

Equipment operation and maintenance is an important part of enterprise equipment management, and it is the basic work for enterprises to ensure safe production and production capacity. By adopting the mobile work order system, work tasks can be directly sent to the smart phone devices of mobile operators, which facilitates the implementation of various tasks and timely feedback on the completed tasks. Operation and maintenance personnel can easily achieve mobile office.

Product description:

Guangdong China Construction Intelligent Control Technology Co., Ltd. designed and developed China Construction Equipment Assets Standardization Management Software-Mobile Work Order, which realizes the mobile, information and intelligent work orders. Make tedious work order business processes more convenient, easier to manage, and more efficient, while enabling managers to play an incomparable advantage in the monitoring of operation and maintenance work and coordinate the allocation of resources and personnel arrangements. It has really improved the service quality of enterprises, improved service response time, enhanced service guarantee capabilities, and greatly improved production efficiency.

Features:

The mobile work order is composed of a server-side program and a mobile APP, which work together to achieve the mobile, information, and intelligent work order.

(A). Server-side system

1. Equipment basic management. Includes equipment card, equipment ledger, equipment file management, a record table that records the design and manufacture of individual equipment, technical processes, initial value, management status, management classification, and important management data. The sub-tables also record the component structure , Auxiliary equipment, random spare parts, random accessories and tools, technical parameters, random data, equipment main account, and equipment file borrowing and other management.

2. Inquiry of work order management process records. The work order execution process includes work order creation, release, cancellation, completion, and evaluation functions.

(II). Mobile APP

The mobile device device system includes: creating work orders, issuing work orders, receiving work orders, completing work orders, evaluating work orders, querying work orders, setting, and synchronizing data.

Responsible leaders can log in to the system or log in to the system through their mobile phones to process orders, withdraw or withdraw;

The orderer processes the received work order at the equipment site, and after completion, registers the completion information, writes a maintenance report, problems, and solutions.

Value:

1. Equipment reminders on site and provide correct implementation work orders. At the equipment site, mobile phone devices can be used to send reminders to equipment operation and maintenance personnel, provide correct implementation work orders, ensure the authenticity and timeliness of equipment operation and maintenance, and avoid manual information acquisition errors and filling errors. The loss of work orders, etc., leads to incomplete and inaccurate equipment operation and maintenance records, which cannot reflect the actual situation of equipment operation and maintenance, and lays hidden dangers for safe production and production plan execution.

2. Handle equipment anomalies in time to ensure the safe operation of the equipment. Through timely work reminders, operation and maintenance personnel can accurately grasp the initial information about equipment failures and take measures to eliminate the failures in a timely manner. Avoid employees who are unfamiliar with the mastery of standards and cannot follow up on equipment abnormalities in a timely manner.

basic configuration

4. Move inventory

Product idea:

Barcode and RFID, as important and basic technologies of the Internet of Things, have been widely used in our work and life. In enterprise equipment spare parts inventory management, barcode and RFID combined with mobile communication applications can greatly improve the efficiency of our enterprise spare parts inventory management.

Product description:

Guangdong Zhongshe Intelligent Control Technology Co., Ltd. designed and developed the China Assets Equipment Assets Standardization Management Software-Mobile Inventory System, which combines barcode, RFID with mobile handheld devices, and mobile networks, and connects enterprise management networks and management systems in parallel to achieve Intelligent mobile inventory management model for enterprise spare parts materials. It makes long-distance, inconvenient network conditions, and quick access to and storage of spare parts materials in multiple warehouses, and inventory becomes easier, greatly reducing the manpower and material input of the enterprise's spare parts warehouse, and also improves the timeliness and accuracy of inventory data and enhances enterprise spare parts Inventory management and control capabilities.

Features:

Warehouse management

Establish electronic management of enterprise asset warehouses, achieve standardized outbound and inbound management, grasp inventory status in a timely manner, and perform inventory reserve level and consumption analysis.

Inventory management

The system installs the mobile inventory software to the mobile intelligent terminal data collector, scans the physical barcode on the spot for comparison, and transfers the inventory results to the system, automatically checks to form the inventory surplus and inventory loss records, and automatically completes the inventory work.

Outbound Management

The system realizes that the unfinished storage order on the server side can be downloaded to the mobile intelligent terminal data collector, a new storage order is created on site, the physical barcode is scanned, and the result is uploaded to the system to complete the work of receiving and storing the spare parts.

Report statistics management

The system has powerful report statistics functions, can output various styles of reports, and supports configurable custom statistics and chart display.

Value:

The perfect combination of mobile inventory and equipment field data collection. Mobile inventory uses mobile intelligent terminals as field work terminals. It introduces bar code and RFID technology to migrate on-site business spare parts to storage, inventory, inventory and other management functions to mobile intelligent terminals, and supports on-site support. Information is imported into the mobile intelligent terminal; the on-site personnel carry out inventory business management and inventory work at the job site in real time or in time. After the business is completed, the mobile intelligent terminal communicates with the back-end inventory management system in time, and automatically combines with the post-management system to automatically complete the out of the warehouse, Synchronization of inventory and inventory data. Easily, efficiently and accurately improve inventory management efficiency and data accuracy.

Use value

According to relevant data statistics, the successful application of a complete set of spare parts materials mobile inventory solution can achieve the following management and economic value for enterprises:

Reduce the search time of spare parts by 50% -91%;

Reduce "lost" spare parts by 40-50%;

Reduce the cost of repeated purchases by 15% -20%;

Increase the use of spare parts materials by 20% -30%.

5, check king

Product idea:

Equipment inspection is the top priority of enterprise equipment management, especially in the process industry that requires high continuity. By adopting the handheld inspection management system, it is possible to directly send work tasks to the inspection equipment of mobile workers, which is convenient for carrying out various tasks and timely understanding the operating status of various parts of the equipment. Combined with various work standards established by the computer system for regular inspection and maintenance, the work items such as equipment inspection items, standard values, lines, inspection periods, and hidden trouble elimination are solidified, providing tools and data support for compliance management of equipment assets , Help to avoid production equipment from errors, defects and hidden dangers and deterioration to failures resulting in downtime, production stoppages, causing irreparable huge losses.

Product description:

Combined with data acquisition instruments, using advanced computer technology and communication technology, the inspection standards, inspection route information, and inspection task information are regularly downloaded and stored in the handheld device. Inspection personnel only need to follow the inspection task guide in the system. It is convenient to collect data and establish an advanced enterprise inspection work mode.

Features:

(A) Server-side system:

1. Equipment basic management. Includes equipment card, equipment ledger, equipment file management, a record table that records the design and manufacture of individual equipment, technical processes, initial value, management status, management classification, and important management data. The sub-tables also record the component structure , Auxiliary equipment, random spare parts, random accessories and tools, technical parameters, random data, equipment main account, and equipment file borrowing and other management.

2. Check and check the basic settings and check process records. The basic settings define the information about the inspection line. The inspection process includes inspection tasks, inspection records, and query functions. During the operation, you only need to define the basic inspection information. The system will automatically generate an inspection plan. After downloading the plan to the handheld device, you can scan the tags according to the system tasks to the inspection point, and perform the inspection work. The equipment is uploaded to the checkpoint checkpoint record function, and the results of the checkpoint can be queried and statistically analyzed.

(II) handheld device system

The handheld device system includes: task download, result upload, input label, check processing, task check, free check, record query, system setting, scan tag storage, exit system and other functions.

The inspection personnel can download the inspection tasks to the inspection subsystem of the handheld device through the inspection king system. According to the inspection routes and items defined therein, and at the required time, they can go to the inspection point [pre-deployed] for inspection work. After the work is completed, upload the results to the system for comparative analysis of the system to provide a basis for preventive maintenance. Zh

Value:

Solidify the inspection work mode, standardize the inspection process, and improve inspection quality. To ensure the authenticity, timeliness of the equipment inspection work and the validity of the inspection result data, to avoid missed or even unchecked inspections during the inspection process, the manager can check the equipment inspection work process through the inspection king system And quality.

Discover equipment anomalies in time to ensure the safe operation of the equipment. Through standard inspection work, equipment abnormalities and hidden dangers are discovered in time, the initial information about equipment failures is grasped, and measures are taken in time to eliminate the failures in the bud stage.

Effectively perform data analysis to obtain equipment failure rules. The inspection results are directly uploaded to the inspection king system database, which can analyze the statistics of the equipment's long-term inspection results, and obtain the key data of equipment failure rules and daily maintenance.

Carry out preventive maintenance work to extend the service life of equipment and reduce production costs of enterprises. Combining various types of data collected by the handheld device of the Inspection King system, and using the information provided by the fault analysis system, management personnel use this as an important basis for formulating pre-maintenance strategies, propose reasonable parts repair and replacement plans, and continuously summarize experience and improve technology Standard to maintain high stability of equipment performance.

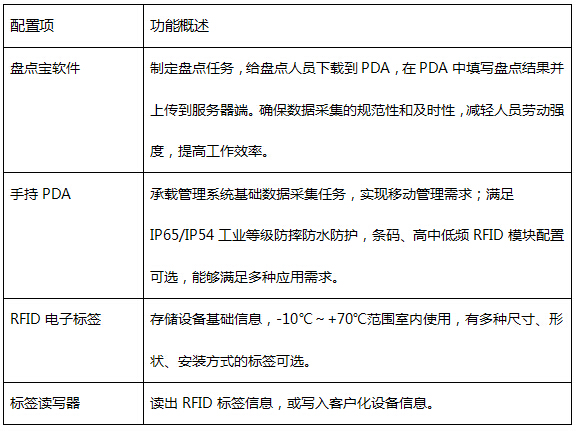

basic configuration

6, inventory

Product idea:

Barcode technology and radio frequency identification RFID technology, as important and basic technologies of the Internet of Things, have been widely used in our work and life. In enterprise equipment asset management, there are also applications of barcode technology and RFID technology. A typical application is the inventory of enterprise assets using barcode technology and RFID technology.

Product description: Combining barcode technology, RFID technology with mobile handheld devices, and mobile networks, connecting the enterprise management network and management system in parallel to achieve intelligent inventory management of enterprise equipment assets. It makes the rapid inventory of equipment assets possible, greatly reduces the human and material investment of the enterprise inventory, also reduces the error rate of inventory, and enhances the efficiency of enterprise asset data collection.

Function introduction: Asset management: Realize the life-cycle management of assets. The four phases of asset introduction, card establishment, asset operation and maintenance, and asset exit are all reflected, sorting out and optimizing asset account management, and grasping the integrity of assets. Archive information.

Warehouse management: Establish the electronic management of enterprise asset warehouses, achieve standardized outbound and inbound management, timely grasp the inventory situation, and perform inventory reserve level and consumption analysis.

Inventory management: The system installs the equipment asset inventory software to the PDA data collector, scans the physical barcode on the spot for comparison, transfers the inventory result to the system, automatically checks to form the inventory profit and inventory loss records, and automatically completes the inventory work.

Report statistics management: The system has powerful report statistics functions, can output various styles of reports, and supports configurable custom statistics and chart display.

Application value: 1. Asset management-Realize multi-state asset management

The inventory system helps enterprise equipment asset ledger management personnel to comprehensively manage the asset ledger. The main businesses include card establishment, relocation, storage, idle, scrap, and allocation, enabling enterprise managers to use equipment cards effectively and conveniently. , Ledger information, and the system provides statistical analysis by equipment category, organization, and geographic area.

2.Inventory management-the perfect combination of inventory and equipment field data collection

Inventory uses PDA as a field work terminal, introduces barcode and RFID technology, transplants on-site business inventory, inventory and other management functions to PDA, and imports on-site support information into PDA; field personnel obtain tasks and work in real-time or in time at the equipment site Support information, collect data on the spot, and then feed the data in the PDA to the inventory system in real time and in time. It is automatically combined with the management system to compare inventory differences and automatically form inventory profit and loss records. Easily, efficiently and accurately improve inventory work efficiency and data accuracy.

3. Use value

According to relevant data statistics, the successful application of a complete set of equipment asset inventory solutions can achieve the following management and economic values for enterprises:

· Reduce device discovery time by 50% -91%;

Reduce equipment “lost” by 40% -50%

· Reduce repeated procurement costs by 15% -20%;

· Increase equipment asset utilization by 20% -30%.

basic configuration

Product

Solution

News

Copyright © 1999-2020 All Rights Reserved 粤ICP备05009780号

© 1999-2020 广东中设智控科技股份有限公司