Product center

China Construction Materials Management System

Product description

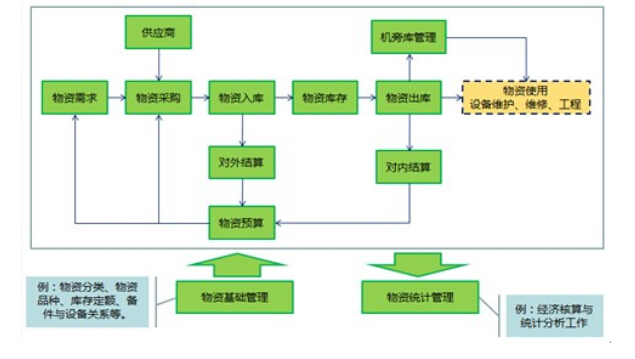

This system adopts advanced management theories and management methods, unifies material management benchmarks, and establishes refined (such as: classification and grading, dynamic monitoring, limited-time work, etc.) material management systems. And in accordance with the actual situation of Chinese enterprise management, combined with industry best practices, a strong and complete material management platform that meets the actual situation of the enterprise can ensure that the company's material management is at a relatively advanced level in the country. Promotion.

Application architecture

Features

Basic management

The basic information part of material management includes the main tasks such as material classification, material code, warehouse catalog, warehouse location code, material management level and safety reserve.

Demand management

Demand management support guides the formation of procurement requirements with material use plans, inventory status, and inventory quotas, and controls actual procurement, inventory status, in-transit status, recent plan implementation, and funding plan status to control purchase demand reviews.

Purchase management

The main goal of procurement management is to establish a material management business process that is in line with modern enterprises, and support consignment procurement, normal procurement, processing procurement, and outsourcing procurement. Use information platform to realize information management and process control of inquiry, bidding and contract. Implement a procurement price control mechanism and support a centralized procurement management model.

Inventory management

Inventory management enables smooth business processes such as material procurement, inventory circulation, and consumption. Establish data models such as price, consumption, and inventory, and support multiple inventory pricing methods such as batch price, average price, and zero price. And through qualitative and quantitative scientific analysis, provide timely and reliable reference data for leadership decision-making. It mainly includes quality inspection management, storage management, allocation management, receipt management, return management, warehouse early warning management, and scrap management.

Supplier management

Establish an objective and fair supplier access mechanism, standardize centralized management of supplier access and qualification review, and carry out regular supplier grade qualification evaluations based on comprehensive historical facts such as contract, delivery, acceptance, warranty, and post-use evaluation. Establish a complete supplier service file to support comparative analysis of multi-angle prices.

Statistical Analysis

The contents of warehouse management involved in the project can be statistically and analyzed from different aspects, different levels, and different angles, and a cost index system that can be broken down into departments and periods is established. And through corresponding statistics and analysis, to provide appropriate decision-making basis for material management departments and leaders, such as: procurement cycle, safety stock, backlog inventory, idle inventory, turnover rate, etc.

Technology Architecture

· This system adopts B / S architecture;

Browser: IE6 and above;

Application middleware: Various application middleware that conforms to Java EE5 and above specifications, such as Websphere, Weblogic, JBoss, etc., can also run on Tomcat5.0 and above

· JRE version: JRE5.0 and above;

Database: relational database of Oracle8i, MS SQL Server 2000, MySQL5.0, DB 2 v95, etc. and corresponding upgraded versions;

· Other: Support LDAP, Windows Active Directory, etc.

Features and advantages

Thin client: This system can run on IE without installing any plug-ins;

· Customizable business process: The user can adjust the business process by using the system's own business process management system according to needs;

· Multiple job reminding methods: You can display the to-do work on the system homepage, or you can remind the task by email, mobile phone text message and dedicated to-do client

· Graphical drive: Operators can work on graphics, which is more intuitive and simple;

· Support multiple integration modes: (a) support integration through TXT files, excel files, etc .; (b) support integration through multiple database objects such as data tables, views, stored procedures; (c) support through HTTP services, Socket service, WebService service and other services to achieve integration;

· System configurability: Various system data required for system operation are maintained by supporting development tools, and users can use supporting tools to adjust as needed;

· Provide multi-level query, you can query in the result set; all fields on the current page can be used as query conditions; query results can be directly output into Excel file or text file;

· Provide multiple page styles, which can be adjusted as needed;

· Operators must "sign" the data to confirm it to become official data and avoid temporary data entering the process;

· Provide multiple authorization modes, that is, authorization can be added, deleted, changed, and checked, or authorized according to different data types. Multiple authorization modes exist simultaneously;

· Provide multi-level authorization to support distributed authorization of group enterprises.

This system is driven by demand, and realizes the synchronization of material demand planning, procurement planning, procurement business management, supplier management, quality management, warehouse management and material flow, capital flow, business flow and workflow, ensuring material prices, procurement cycle, Key management objects such as payment of funds and supplier services meet corporate management standards.

This system takes a reasonable procurement cycle as the core, and stipulates and monitors each supplier, demand plan, procurement plan, bidding, contract management, procurement operation, payment of funds, transportation, arrival, quality inspection and measurement, storage, receipt and so on. The time standard and time process of the work link realize the synergy of the time process of the company's material flow, capital flow, information flow and work flow. Through the coordination of the work flow, the work efficiency of each link such as demand, procurement, storage and distribution is reduced, and Transaction costs and management costs.

Value

This system adopts advanced information management technology and management methods. By setting management benchmarks, it controls suppliers, prices, demand plans, procurement plans, contracts, cost budgets and capital controls, inventory, procurement operation time process, procurement personnel behavior and procurement. Management analysis and early-warning control are implemented to make the purchase price, purchase cycle, and inventory amount to the lowest, shortest, smallest, and economical and reasonable target.

Through the realization of each of the above goals, and through the introduction of business process dynamic management technology, it effectively guarantees the control of the management process, the management benchmark, the procurement process and quality control, so that material management provides a reliable guarantee for the rapid development of the enterprise, and The continuous improvement and development of material management provides information technology support.

Product

Solution

News

Copyright © 1999-2020 All Rights Reserved 粤ICP备05009780号

© 1999-2020 广东中设智控科技股份有限公司